Call us

PRODUCTS

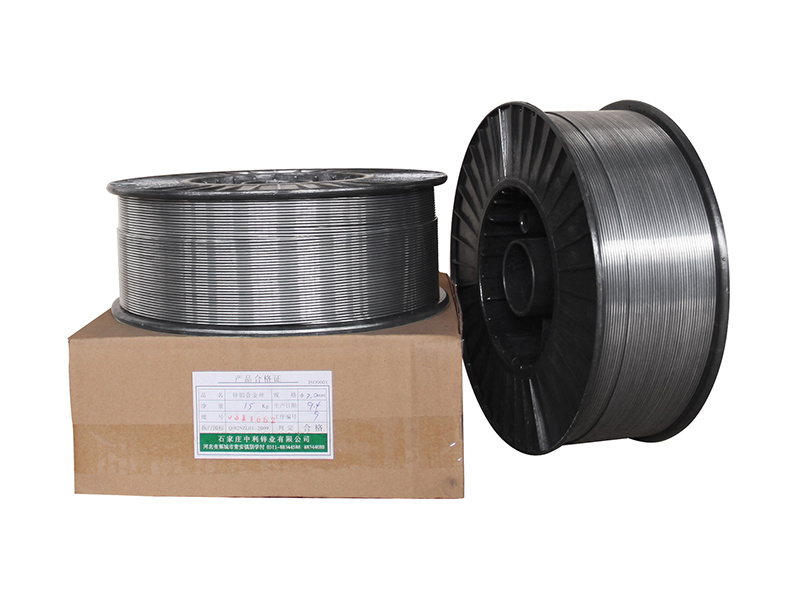

Zinc aluminum wire

Grade: 85/15(Zn85Al15) 95/05 98/02

Specifications: Φ0.8mm-Φ5mm

Key words:

Tel:

Zinc aluminum wire

More details

Product introduction

With 20 years experience in producing zinc-aluminium alloy wire, we provide a wide range of zinc\ aluminium/ zinc alloy/ aluminium alloy of the highest product quality. In addition, we offer customized special wire to meet your special solution for specific applications.

Key benefits

* Smooth surface, no oil and burr, no scratch, no scar.

* Remarkable adhesiveness.

*Compared with pure zinc wire and pure aluminium wire, zinc-aluminium alloy coating can prolong the life of steel 5-10 times.

* All technical indicators comply with the EU ROHS requirements on environmental protection.

* High purity enables low energy consumption.

Application

Zinc aluminium wire can be used for thermal spraying in anti-corrosion surface treatment technology, such as, steel structure, container, bridges, derrick, storage tank, power towel, poles, capacitors, metal bracket, ductile cast iron pipes, transportation equipment, etc.

Packing

1、Plastic spool : 10kgs/spool, 15kgs/spool

Size: outer dia 270mm, inner dia 52mm, height 105mm

2、Drum:

250kg drum: outer dia 460mm, height 280mm

100kg drum: outer dia 570mm, height 380mm

50kg drum: outer dia 570mm, height 740mm

3、Coil: 20 kg /coil, 25 kg/coil

Size: external dia 430mm, inner dia 270mm, height 90mm

Related Products

Contact

Add:Pengxue Industrial Park, Gaocheng District, Shijiazhuang, Hebei Province, China.

Follow us

Message